I-BS EN 10210 amashubhu ensimbiziyizingxenye ezingenalutho eziqedwe ngokushisa zezinsimbi ezingaxutshiwe neziwuhlamvu oluhle zohlu olubanzi lwezinhlelo zokusebenza zesakhiwo nesemishini.Iqukethe izingxenye eziyindilinga, eziyisikwele, eziwunxande, neziyiqanda.

I-EN 10210 ne-BS EN 10210 ngamazinga afanayo kodwa anezinhlangano ezahlukene.

Izinkinobho Zokuzulazula

I-BS EN 10210 Ukuhlukaniswa

I-BS EN 10210 Ububanzi Bosayizi

Ama-Raw material

I-BS EN 10210 Igama Lensimbi

Izimo Zokulethwa kwe-BS EN 10210

Ukwakhiwa Kwekhemikhali kwe-BS EN 10210

Izakhiwo Zemishini ye-BS EN 10210

Izivivinyo Zomthelela

Ukushisela

Ukubekezelela Dimensional

Ukubukeka Kobuso

Kufakwe amagalani

Ukulungiswa Kweziphambeko Zobuso

I-BS EN 10210 Ukumaka

Izinhlelo zokusebenza

Imikhiqizo Yethu Ehlobene

I-BS EN 10210 Ukuhlukaniswa

Ngohlobo Lwensimbi

Izinsimbi ezikhethekile ezingaluliwe nezihlanganisiwe

Izinsimbi ezingaluliwe:S235JRH, S275JOH ,S275J2H, S355JOH, S355J2H, S355K2H , S275NH,S275NLH,S355NH,S355NLH.

Izinsimbi ezikhethekile ezihlanganisiweI-S420NH, S420NLH, S460NH, S460NLH.

Indlela elula yokuhlonza yile: egameni lensimbi, uma amandla okukhiqiza wenkomba eqala ngenombolo '4', yensimbi ye-alloy.

Ngenqubo Yokukhiqiza

Izingxenye ezingenalutho zesakhiwo kufanele zenziwe nguizinqubo ezingenamthungo noma ezishiselwe.

I-Seamless ihlanganisa: i-hot-finished and cold-finished

Ama-welds avamile ahlanganisa i-Electric Resistance Welding (ERW) kanye ne-submerged Arc Welding (SAW): LSAW, SSAW.

Izingxenye eziyizigodi ezishiselwe ngogesi ngokuvamile azidingi ukusikwa kwe-weld yangaphakathi.

Nge-Cross-section Shape

I-CHS: izingxenye eziyizigodi eziyindilinga;

I-RHS: izingxenye eziyisikwele noma eziwunxande;

EHS: izingxenye ezingenalutho ze-elliptical;

Lesi sihloko sihlelwe yi-circular cross-section (CHS) yokuqukethwe okufanele.

I-BS EN 10210 Ububanzi Bosayizi

Ubukhulu bodonga: ≤120mm

Ububanzi bangaphandle:

Umjikelezo (CHS): Ububanzi bangaphandle≤2500 mm;

Isikwele (RHS): Ububanzi bangaphandle≤ 800 mm × 800 mm;

Unxande (RHS): Ububanzi bangaphandle≤750 mm × 500 mm;

Okusaqanda (EHS): Ububanzi bangaphandle≤ 500 mm × 250 mm.

Ama-Raw material

Insimbi engahlanganisiwe necolekileyo yokusanhlamvu.

Insimbi engafakwanga izimfanelo ezine ezithi JR, JO, J2, kanye ne-K2 zicacisiwe.

Izinsimbi zokusanhlamvu ezinhle: izimfanelo ezine ze-N ne-NL zicacisiwe.

Izinsimbi zokusanhlamvu ezinhle ziyizinsimbi ezinesakhiwo sokusanhlamvu esihle, ezinosayizi wezinhlamvu ze-ferrite ≥ 6.

I-BS EN 10210 Igama Lensimbi

Ezingxenyeni ezingenalutho zensimbi engeyona i-alloy igama lensimbi liqukethe

Isibonelo: BS EN 10210-S275J0H

iqukethe izingxenye ezine:S, 275, J0, kanye no-H.

1.S: kukhombisa ukuthi insimbi yesakhiwo.

2.Inani lenombolo(275): ukujiya ≤ 16mm kobuncane bamandla esivuno ashiwo, ku-MPa.

3.JR: ikhombisa ukuthi kumazinga okushisa asekamelweni anezici ezithile zomthelela;

J0: ikhombisa ukuthi ku-0 ℃ enezici ezithile zomthelela;

J2 noma K2: kukhonjiswe ku -20 ℃ ngezici ezithile zomthelela;

4.H: ikhombisa izigaba ezingenalutho.

Ezingxenyeni ezingenalutho zensimbi yokusanhlamvu, igama lensimbi liqukethe

Isibonelo: EN 10210-S355NLH

Iqukethe izingxenye ezinhlanu:S, 355, N, L, kanye no-H.

1. S: ikhombisa insimbi yesakhiwo.

2. Inani lenombolo(355): ukujiya ≤ 16mm ubuncane obubekiwe bamandla esivuno, iyunithi i-MPa.

3. N: ukuginqika okujwayelekile noma okujwayelekile.

4. L: izici ezithile zomthelela ku -50 °C.

5.H: ichaza isigaba esingenalutho.

Izimo Zokulethwa kwe-BS EN 10210

JR, J0, J2 kanye ne-K2 - ukushisa kuphelile.

I-N ne-NL - ijwayelekile.Okujwayelekile kufaka phakathi ukugoqwa okujwayelekile.

I-JR, J0, J2 kanye ne-K2 - iyasebenza kakhulu

I-N kanye ne-NL - Ukulinganisa.Ukwejwayelekile kuhlanganisa ukugoqa okujwayelekile.

Kungase kudingeke ukuthi izingxenye ezingenalutho ezingenamthungo ezinogqinsi olungaphezulu kuka-10 mm, noma lapho i-T/D ingaphezu kuka-0,1, ukusebenzisa ukupholisa okusheshisiwe ngemva kokuqinisa ukuze kufezwe isakhiwo esihlosiwe, noma ukucisha uketshezi kanye nokushisa ukuze kuzuzwe ukupholisa okucacisiwe. izakhiwo.

Ezingxenyeni ezingenalutho ezingenamthungo ezinobukhulu bodonga obudlula u-10 mm, noma uma i-T/D ingaphezu kuka-0.1, ukupholisa okusheshisiwe ngemva kokwenza i-austenitization kungase kudingeke ukuze kuzuzwe isakhiwo esifiswayo, noma ukucisha uketshezi nokufudumeza ukuze kuzuzwe izici zomshini ezishiwo.

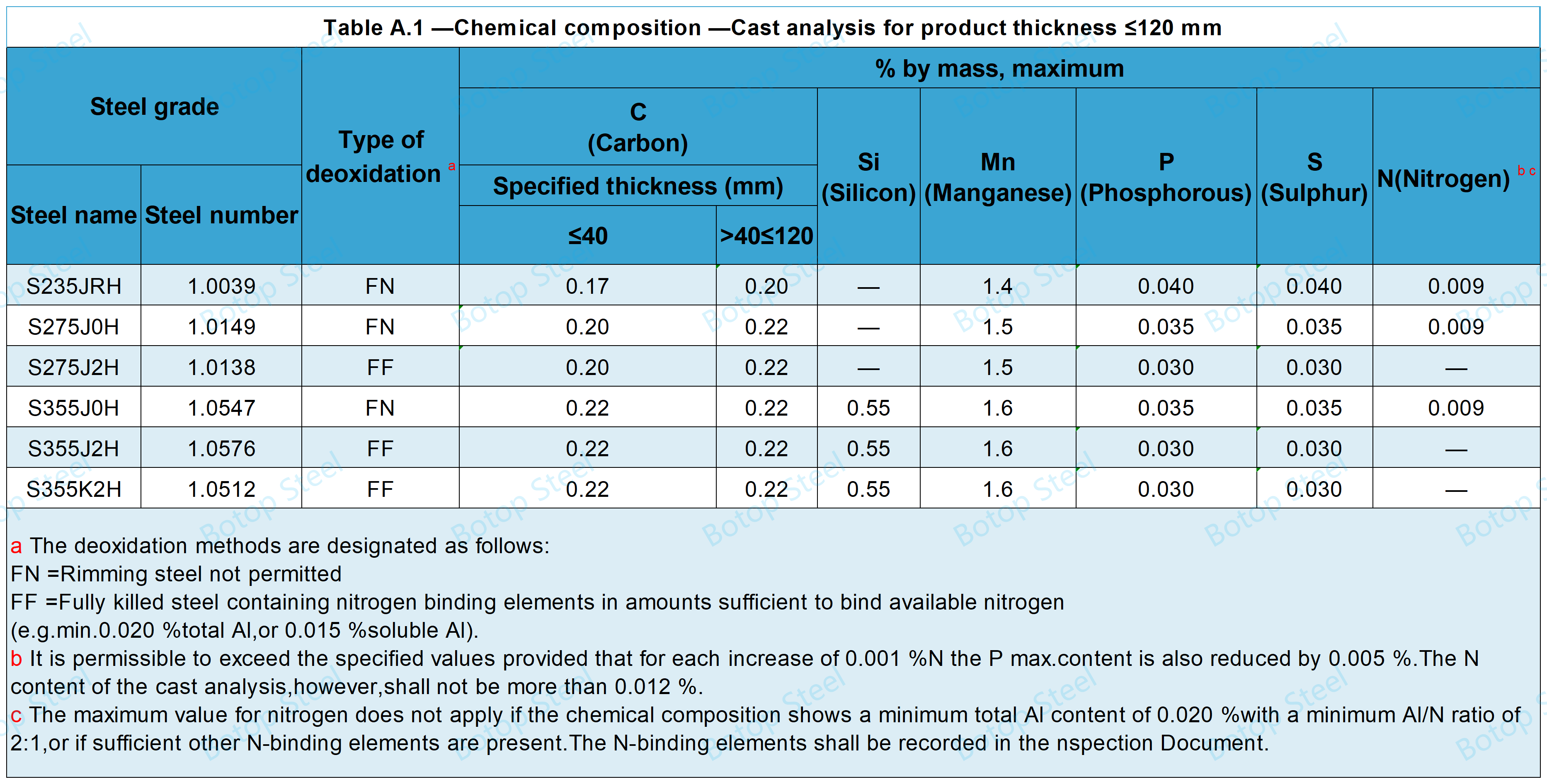

Ukwakhiwa Kwekhemikhali kwe-BS EN 10210

Izinsimbi ezingezona i-alloy - Ukwakheka kwamakhemikhali

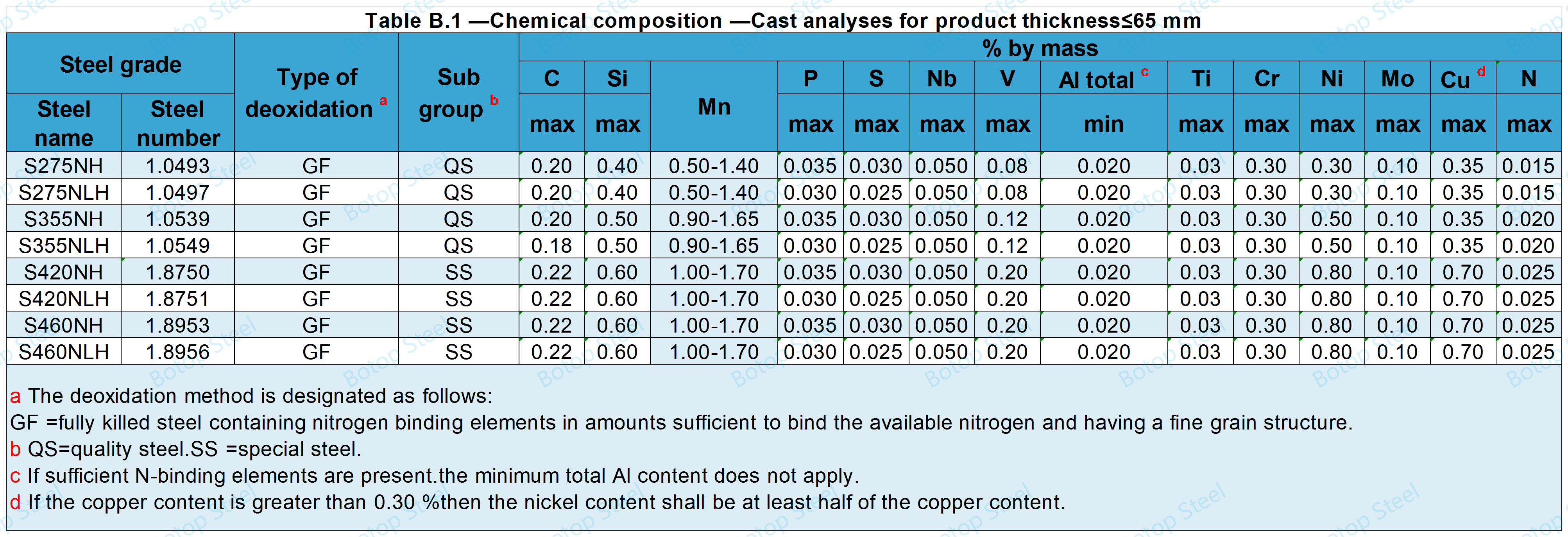

Fine Grain Steels - Ukwakheka kwamakhemikhali

Lapho kunqunywa i-CEV ifomula elandelayo izosetshenziswa:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

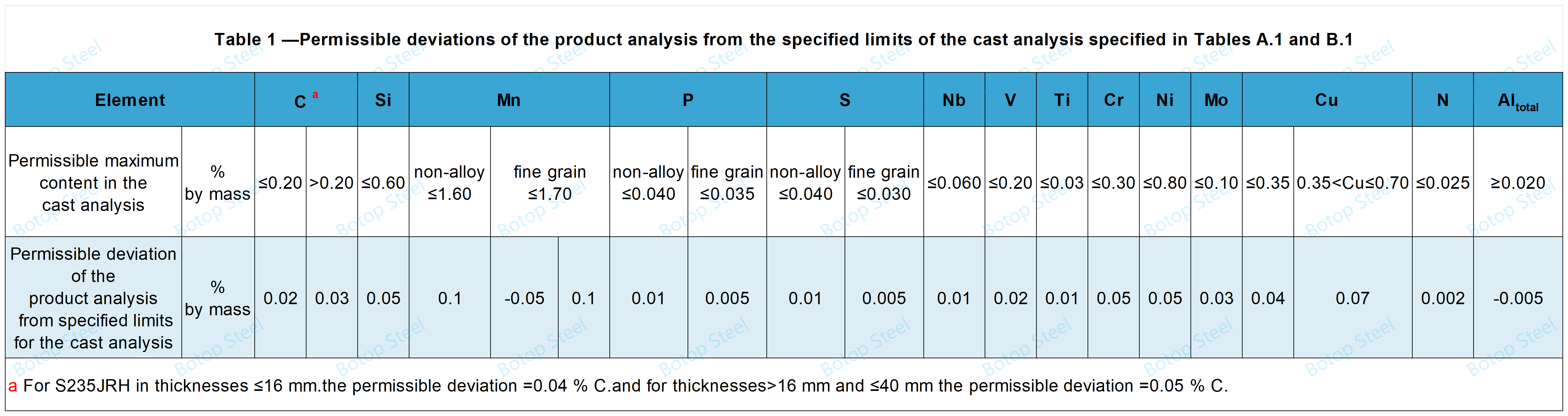

Ukuchezuka Ekubunjweni Kwamakhemikhali

Izakhiwo Zemishini ye-BS EN 10210

Ukunciphisa ingcindezi ngaphezu kuka-580 °C noma isikhathi esingaphezu kwehora elilodwa kungase kuholele ekuwohlokeni kwezakhiwo zemishini.

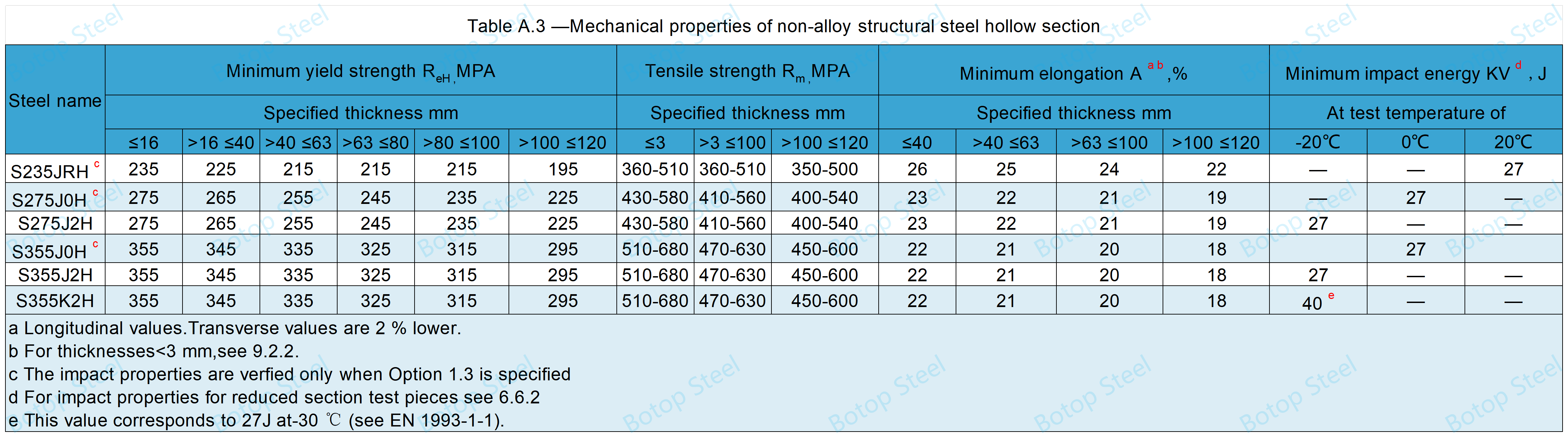

Izinsimbi ezingezona i-alloy - Izakhiwo Zemishini

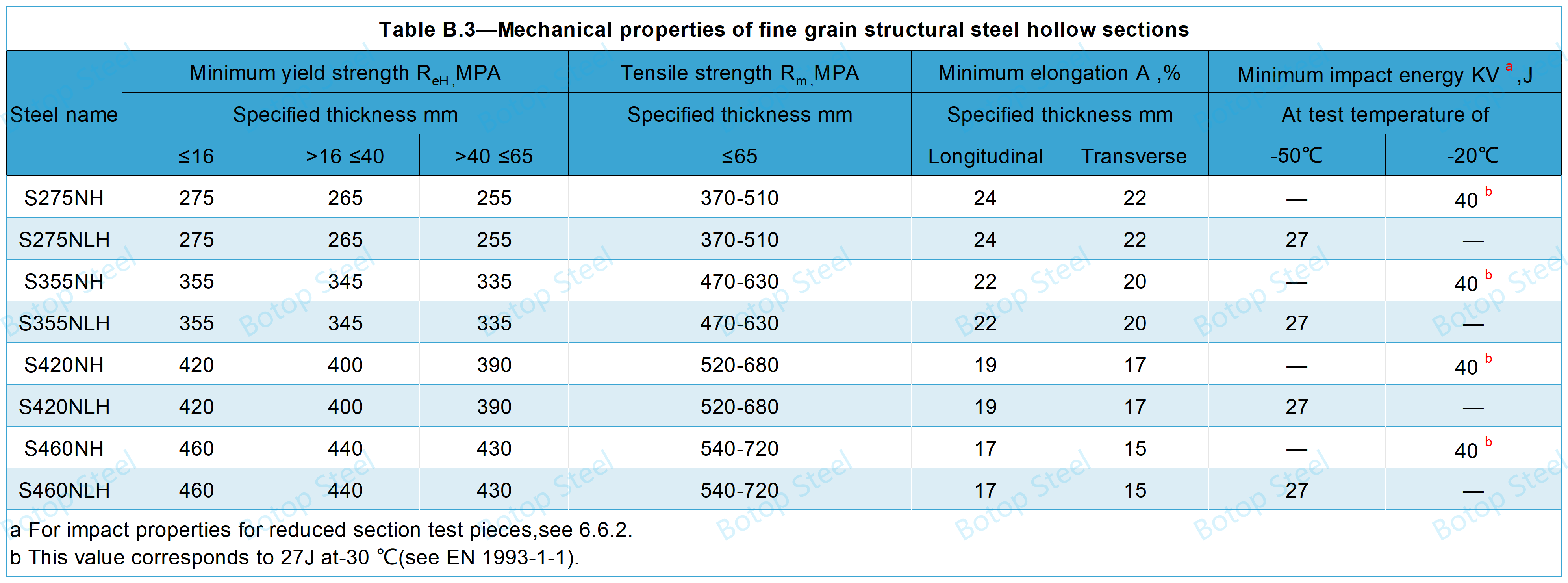

Fine Grain Steels - Mechanical Properties

Izivivinyo Zomthelela

Ukuhlolwa komthelela akudingekile uma ubukhulu obucacisiwe < bungu-6 mm.

Izibonelo ezijwayelekile ezinophawu lwe-V ngokuya nge-EN 10045-1 zizosetshenziswa.

Uma ukushuba komkhiqizo okuzisholo kunganele ukulungiselela ama-specimens ajwayelekile, ukuhlolwa kuzokwenziwa kusetshenziswa izibonelo ezinobubanzi obungaphansi kuka-10 mm, kodwa bungabi ngaphansi kuka-5 mm.

Ukushisela

Izinsimbi ku-BS EN 10210 ziyakwazi ukushisela.

I-EN 1011-1 kanye ne-EN 1011-2 icacisa izidingo ezijwayelekile zemikhiqizo eshiselwe.

Ukuqhekeka okubandayo endaweni yokushisela kuyingozi enkulu njengoba ukushuba komkhiqizo, izinga lamandla, kanye nokukhuphuka kwe-CEV.

Ukubekezelela Dimensional

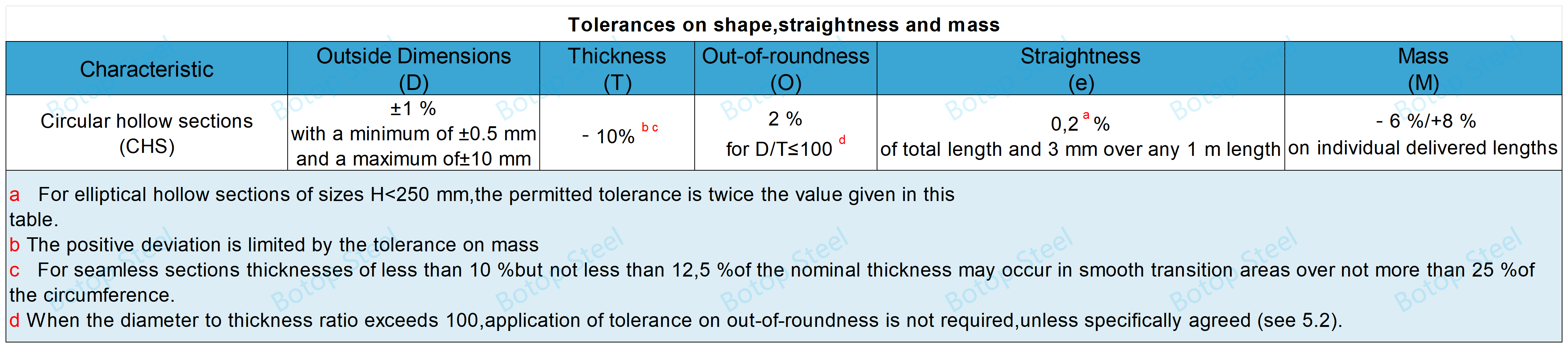

Ukubekezelela Isimo, UkuQopha kanye NeMisa

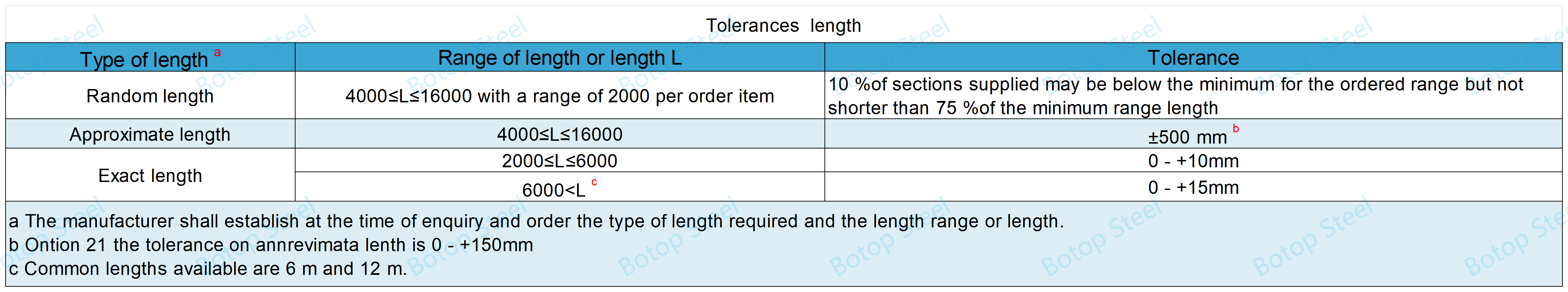

Ukubekezelela Ubude

Ukuphakama Kwe-Seam ye-SAW Weld

Ukubekezelela ukuphakama kwe-weld seam yangaphakathi nangaphandle yezingxenye ezingenalutho ze-arc ezishiselwe.

| Ubukhulu, T | Ubukhulu bobude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Izinga le-BS EN 10210 limboza yomibili imikhiqizo yengxenye engenamthungo neshiselwe eshiselwe okushisayo eqediwe.Izinqubo zokushisela eziyinhloko yi-resistance welding (ERW) kanye ne-submerged arc welding (SAW).Amapayipi ensimbi e-ERW awabonakali, kuyilapho ama-SAW evamise ukuba mabi futhi abonakale kakhulu ngenxa ye-SAW.

Ukubukeka Kobuso

Ingaphezulu lizoba nesiphetho esibushelelezi esihambisana nendlela yokukhiqiza esetshenzisiwe;

Uma ukujiya kungaphakathi kokubekezelelana, amaqhuqhuva, ama-grooves, noma ama-longitudinal grooves angajulile abangelwa inqubo yokukhiqiza avunyelwe.

Kufakwe amagalani

Imikhiqizo eku-BS EN 10210 ilungele ukwelashwa kwe-dip galvanizing eshisayo.

I-EN ISO 1461 kufanele isetshenziselwe ukucacisa izidingo zokumboza.

Izingubo ze-Zinc zisetshenziswa ngokucwiliswa esixazululweni esincibilikisiwe esiqukethe okungenani i-98% yokuqukethwe kwe-zinc.

Ukulungiswa Kweziphambeko Zobuso

Ukulimala okungaphezulu kungase kususwe ngokugaya umkhiqizi, inqobo nje uma ukujiya okulungisiwe kungengaphansi kobukhulu obuncane obuvunyelwe.

Uma kukhiqizwa inqubo yokushisela, ukulungiswa kwama-welds akuvunyelwe ngaphandle kwe-arc welding engaphansi kwamanzi.

Ipayipi lensimbi elingelona ingxubevange lingalungiswa ngokushisela umzimba wepayipi.Ipayipi lensimbi ye-alloy angeke lilungiswe ngokushisela umzimba.

I-BS EN 10210 Ukumaka

Okuqukethwe kokumaka ipayipi lensimbi kufanele kuqukathe:

igama lensimbi, isb EN 10210-S275JOH.

igama noma uphawu lokuhweba lomkhiqizi.

inombolo kamazisi, isb inombolo ye-oda.

I-BS EN 10210 amashubhu ensimbi angamakwa ngezindlela ezahlukahlukene zokuqinisekisa ukukhonjwa kalula nokulandeleka, kungaba ngokudweba, ukugxiviza, amalebula okunamathela, noma amalebula engeziwe, angasetshenziswa ngawodwana noma ahlanganiswe.

Izinhlelo zokusebenza

Ngenxa yamandla ayo aphezulu, ukuqina okuhle, kanye nokushisela, i-BS EN 10210 iyakwazi ukumelana nenhlobonhlobo yendawo nezimo zokulayisha futhi isetshenziswa kabanzi ezinhlelweni ezihlukene zesakhiwo.

Izakhiwo zokwakha: isb. amathambo ezakhiwo eziphakeme, izakhiwo zophahla ezinkundleni zemidlalo, nezinto ezisekela amabhuloho.

Onjiniyela bamakhemikhali: amafreyimu nezisekelo zemishini nemishini esindayo.

I-Civil Engineering: njengezisekelo zomhubhe, amakholomu ebhuloho, nezinye izakhiwo ezithwala umthwalo.

Ingqalasizinda yezokuthutha: kufaka phakathi izingxenye zemigwaqo namabhuloho wesitimela.

Umkhakha wezamandla: isb. imibhoshongo yenjini yomoya kanye nezinye izingxenye zesakhiwo sezinsiza zamandla.

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Amathegi: bs en 10210, zu 10210,s275j2h,s275j0h,s355j2h.

Isikhathi sokuthumela: Apr-25-2024