Okokuqala, isimiso esiyisisekelo seithubhu engenamthungoukugingqa okuqhubekayo futhihot rolling:

- Ukugingqika okuqhubekayo kweshubhu okungenamthungo: Le nqubo ihilela ukugingqa amabhilidi ochungechungeni lwamaroli acijile.I-billet igxilile ngokuqhubekayo futhi yelulwe ukuze ibe nefomuamashubhu ensimbi angenamthungongaphandle kokuphazamiseka.

- I-Hot Rolling: Kule nqubo, i-billet iqala ukushisisa ibe yizinga lokushisa elithile bese igoqwa ngochungechunge lwamayunithi aginqikayo ukuze ilolonge libe yipayipi elingenamthungo.

Okwesibili, umehluko wenqubo phakathi kweshubhu engenamthungo eqhubekayo nokuginqika okushisayo:

- Ukucubungula ukunemba:

- Ukugingqika okuqhubekayo kweshubhu elingenamthungo: Ukusetshenziswa kwamaroli e-groove ekugingqeni okuqhubekayo kuvumela ukwanda kwendawo yokuxhumana, kunciphisa ukuchezuka phakathi nenqubo yokugingqa futhi kubangele ukunemba okuphezulu komshini.Ukunwebeka okuqhubekayo nokucindezelwa kwe-billet kuphinde kube nomthelela ekuzuzeni ukunemba okukhulu.

- Ukuginqika okushisayo: Ukuginqika okushisayo kungathonywa izinga lokushisa nezinye izici, kukwenze kuthambekele kakhulu ekuguquguqukeni okungalingani kanye nokuguqulwa kwemikhono.Ngenxa yalokho, ukunemba okutholakala ngokugingqika okushisayo kuvame ukuba ngaphansi kancane uma kuqhathaniswa neshubhu engenamthungoukuginqika okuqhubekayo.

- Ukubukeka kwemikhiqizo eqediwe:

- Ukugingqika okuqhubekayo kweshubhu elingenamthungo: Imikhiqizo eqediwe yokugingqa okuqhubekayo ngokuvamile inokubukeka okushelelayo okunokukhubazeka okuncane kanye nemibimbi.

- I-Hot Rolling: Imikhiqizo eqediwe yokugoqa okushisayo ingaba nama-roll nick, ama-surface roughness, nokunye ukungapheleli.

- Ububanzi besicelo:

- Ukugingqika okuqhubekayo kweshubhu engenamthungo: Le nqubo ifaneleka kahle ukukhiqiza ukunemba okuphezulu namandla aphezulu.amapayipi ensimbi angenamthungo, ikakhulukazi amapayipi anobubanzi obukhulu nalawo anezindonga eziwugqinsi.

- Ukugoqa okushisayo: Ukugoqa okushisayo kulungele kangcono ukukhiqizwa kwamapayipi anezindonga ezincane kanye namapayipi ensimbi anezinga elincane.

Okwesithathu, umehluko wokusebenza phakathi kokugingqika okuqhubekayo kweshubhu engenamthungo kanye nokuginqika okushisayo:

- Amandla:

- Ukugingqika okuqhubekayo kweshubhu engenamthungo: Ukunemba okuphezulu kokucubungula ekugingqikeni okuqhubekayo kubangela amandla ahlobene aphezulu kumapayipi ensimbi akhiqizwayo.

- Ukuginqika okushisayo: Ngenxa yengcindezi ye-shear okuhlangatshezwane nayo ekugingqikeni okushisayo, ukuguqulwa okuncane kungase kwenzeke, okuholela emandleni aphansi uma kuqhathaniswa nokugingqika okuqhubekayo kweshubhu.

- Izakhiwo zemishini:

- Ukugingqika okuqhubekayo kweshubhu okungenamthungo: Isakhiwo sangaphakathi samapayipi akhiqizwa ngokugoqeka okuqhubekayo siminyene, okuholela ezicini ezingcono zokusilungisa, ikakhulukazi ngokwamandla aqinile namandla esivuno.

- I-Hot rolling: Njengoba ukushisa okushisayo kuthinteka izinga lokushisa, isakhiwo sangaphakathi singase singaminyene kancane, okuholela ezicini zemishini ezingaphansi kancane.

- Ukusebenza kokwakha:

- Ukugingqika okuqhubekayo kweshubhu elingenamthungo: Amapayipi enziwe ngokugoqeka okuqhubekayo okungenamthungo abonisa izakhiwo ezinhle zokubumba, eziwenza afanelekele izidingo ezihlukahlukene zokusebenza ezibandayo nezishisayo.

- I-Hot Rolling: I-Hot Rolling ibonakala ngokusebenza kabi kwe-forging ngenxa yethonya lokushisa ngesikhathi sokucubungula.

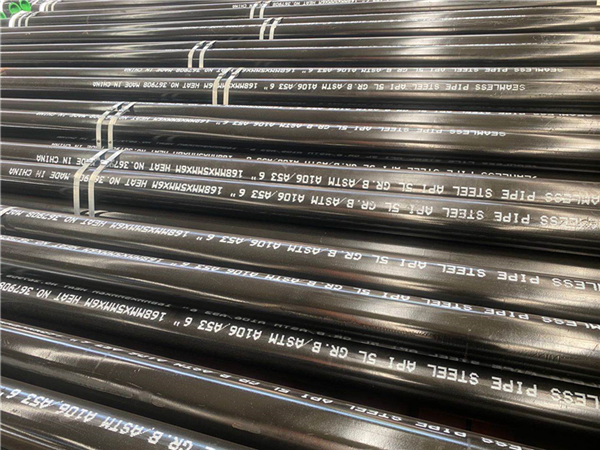

Sengiphetha, ishubhu elingenamthungo ukugingqa nokuginqika okushisayo kuyahluka ngokomgomo, inqubo, nokusebenza.Ukugingqa okuqhubekayo kweshubhu engenamthungo kulungele ukukhiqiza ububanzi obukhulu futhi obunodonga oluwugqinsiamapayipi ensimbingokunemba okuphezulu nokubukeka okuhle.Ngakolunye uhlangothi, ukugoqa okushisayo kulungele kangcono ukukhiqiza amapayipi ensimbi anezindonga ezincane nezincane ngenani eliphansi uma kuqhathaniswa.Kuye ngezidingo ezithile, abafundi bangakhetha inqubo yokukhiqiza ipayipi yensimbi efanele.

Isikhathi sokuthumela: Nov-14-2023