I-ASTM A672ipayipi lensimbi elenziwe ngepuleti lekhwalithi yomkhumbi ocindezelayo,I-Electric-Fusion-Welded (EFW)ngesevisi enengcindezi ephezulu emazingeni okushisa aphakathi nendawo.

Izinkinobho Zokuzulazula

I-ASTM A672 Isigaba Sebanga

I-ASTM A672 Isigaba Sokuhlukaniswa

I-ASTM A672 Ubukhulu Ububanzi

Izinyathelo Zokushisela

Ukwelashwa Kokushisa

Izingxenye Zekhemikhali

Tension Test

Ukuhlolwa kwe-Transverse-Guided-Weld-Bend

Ukuhlolwa Kwengcindezi

Ukuhlolwa kwe-Radiographic

Ukubekezelelana kwe-Dimensional kwe-ASTM A672

Ukubukeka kwe-ASTM A672

Amaphutha kanye Nokulungisa

Ukumakwa kwe-ASTM A672

Ukusetshenziswa kwe-ASTM A672 Steel Pipe

Imikhiqizo Yethu Ehlobene

I-ASTM A672 Isigaba Sebanga

Ihlukaniswa ngokohlobo lwepuleti elisetshenziselwa ukwakha amashubhu ensimbi.

Amabanga ahlukene amelela ukwakheka kwamakhemikhali okuhlukene kanye nezakhiwo zemishini zokucindezela okuhlukile nezimo zokushisa.

| Ibanga lePipe | Uhlobo Lwensimbi | Ukucaciswa kwe-ASTM | |

| Cha. | Ibanga | ||

| A 45 | ikhabhoni engenalutho | I-A285 / A285M | A |

| A50 | ikhabhoni engenalutho | I-A285 / A285M | B |

| A 55 | ikhabhoni engenalutho | I-A285 / A285M | C |

| B 60 | plain carbon, wabulawa | I-A515 / A515M | 60 |

| B 65 | plain carbon, wabulawa | I-A515 / A515M | 65 |

| B 70 | plain carbon, wabulawa | I-A515 / A515M | 70 |

| C 55 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516 / A516M | 55 |

| C 60 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516 / A516M | 60 |

| C 65 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516 / A516M | 65 |

| C70 | ikhabhoni engenalutho, ibulewe, okusanhlamvu okuhle | I-A516 / A516M | 70 |

| D70 | i-manganese-silicon, ejwayelekile | I-A537 / A537M | 1 |

| D80 | manganese-silicon, Q&TA | I-A537 / A537M | 2 |

| H75 | manganese-molybdenum, evamile | I-A302 / A302M | A |

| H80 | manganese-molybdenum, evamile | I-A302 / A302M | B, C, noma D |

| j80 | manganese-molybdenum, Q&TA | I-A533 / A533M | Cl-1B |

| j90 | manganese-molybdenum, Q&TA | I-A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | I-A533 / A533M | Cl-3B |

| L 65 | i-molybdenum | I-A204 / A204M | A |

| L 70 | i-molybdenum | I-A204 / A204M | B |

| L 75 | i-molybdenum | I-A204 / A204M | C |

| N 75 | i-manganese-silicon | I-A299 / A299M | A |

AI-Q&T = ivaliwe futhi ithambile.

ВNoma yiliphi ibanga linganikezwa.

Singaqale sinqume uhlobo lwepayipi lensimbi ngezinhlamvu ezisebangeni.

Amabanga aqala ngezinhlamvu A, B, kanye no-C avame ukukhombacarbon steel pipe.

Amabanga aqala ngezinhlamvu D, H, J, L, kanye no-N akhombisai-alloy steel pipe.

I-ASTM A672 Isigaba Sokuhlukaniswa

Amashubhu ahlukaniswa ngokohlobo lokwelashwa okushisa akutholayo phakathi nenqubo yokukhiqiza nokuthi ahlolwe yini nge-radiographical futhi ahlolwe ingcindezi.

| Ikilasi | Ukwelashwa kokushisa epayipini | I-Radiography, bheka inothi: | Ukuhlolwa kwengcindezi, bheka inothi: |

| 10 | akukho | akukho | akukho |

| 11 | akukho | 9 | akukho |

| 12 | akukho | 9 | 8.3 |

| 13 | akukho | akukho | 8.3 |

| 20 | ukucindezeleka kuphelile, bheka 5.3.1 | akukho | akukho |

| 21 | ukucindezeleka kuphelile, bheka 5.3.1 | 9 | akukho |

| 22 | ukucindezeleka kuphelile, bheka 5.3.1 | 9 | 8.3 |

| 23 | ukucindezeleka kuphelile, bheka 5.3.1 | akukho | 8.3 |

| 30 | okwejwayelekile, bheka 5.3.2 | akukho | akukho |

| 31 | okwejwayelekile, bheka 5.3.2 | 9 | akukho |

| 32 | okwejwayelekile, bheka 5.3.2 | 9 | 8.3 |

| 33 | okwejwayelekile, bheka 5.3.2 | akukho | 8.3 |

| 40 | ijwayelekile futhi inolaka, bheka 5.3.3 | akukho | akukho |

| 41 | ijwayelekile futhi inolaka, bheka 5.3.3 | 9 | akukho |

| 42 | ijwayelekile futhi inolaka, bheka 5.3.3 | 9 | 8.3 |

| 43 | ijwayelekile futhi inolaka, bheka 5.3.3 | akukho | 8.3 |

| 50 | ucime futhi uthukuthele, bheka 5.3.4 | akukho | akukho |

| 51 | ucime futhi uthukuthele, bheka 5.3.4 | 9 | akukho |

| 52 | ucime futhi uthukuthele, bheka 5.3.4 | 9 | 8.3 |

| 53 | ucime futhi uthukuthele, bheka 5.3.4 | akukho | 8.3 |

Ukunakwa okukhethekile kufanele kukhokhwe ekushiseni kwesevisi okulindelekile lapho kukhethwa isigaba sezinto ezifanele.Bheka imininingwane ye-ASTM A20/A20M.

I-ASTM A672 Ubukhulu Ububanzi

Ibanga losayizi abanconyiwe:DN≥400mm[16 in] kanye ne-WT≤75mm[3 in].

Kwabanye osayizi bepayipi, inqobo nje uma ihlangabezana nazo zonke ezinye izidingo zalokhu kucaciswa, ingasetshenziswa futhi.

Izinyathelo Zokushisela

Ama-seams kufanele ashiselwe kabili, angene ngokugcwele.

Ama-welds azokwenziwa ngesandla noma ngokuzenzakalelayo ngenqubo kagesi efaka ukufakwa kwensimbi yokugcwalisa.

Ama-welds angase ahlolwe kusetshenziswa i-radiography futhi kufanele alandele izinhlinzeko eziseSigabeni VII UW-51 se-ASME Boiler kanye Nekhodi Yomkhumbi Wokucindezela.

Ubude be-weld akumele budlule ku-3 mm [1/8 in].

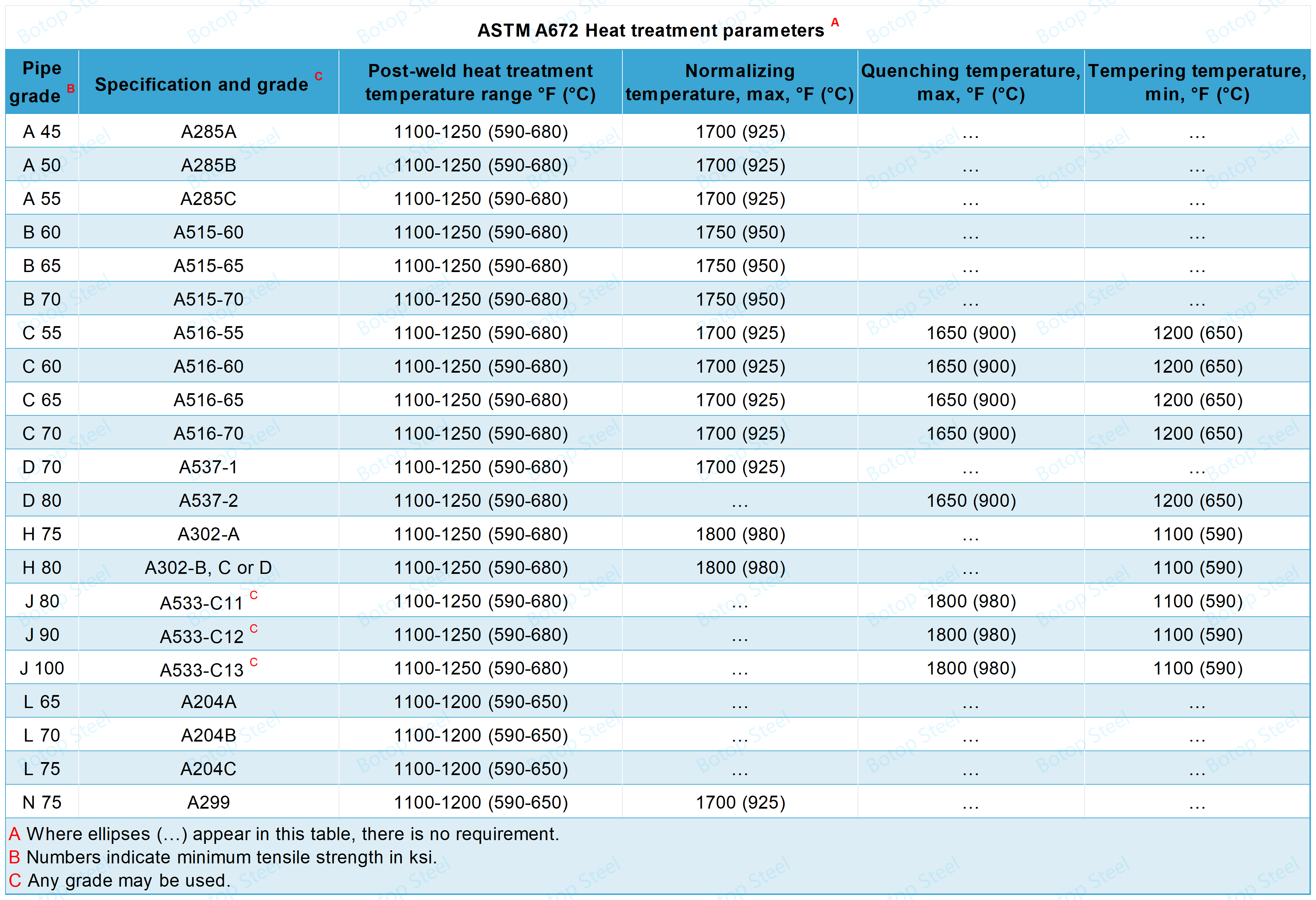

Ukwelashwa Kokushisa

Wonke amakilasi ngaphandle kuka-10, 11, 12, no-13 azophathwa ukushisa esithandweni okulawulwayo kuye ku-±25 °F[± 15°C]:

Amakilasi 20, 21, 22, kanye nama-23

Ipayipi kufanele lishise ngendlela efanayo phakathi kwezinga lokushisa langemva kokushisela elikhonjiswe kuThebula 2 okungenani libe yi-1 h/in.[0.4 h/cm] ukujiya noma ihora elingu-1, kuye ngokuthi yikuphi okukhulu.

Amakilasi 30, 31, 32, kanye nama-33

Ipayipi kufanele lishiswe ngokufanayo libe izinga lokushisa ebangeni le-austenitizing futhi lingadluli izinga lokushisa eliphakeme elijwayelekile elikhonjiswe kuThebula 2 bese lipholiswa ngokulandelayo emoyeni ekamelweni lokushisa.

Amakilasi 40, 41, 42, kanye nama-43

Ipayipi kufanele lijwayele.

Ipayipi kufanele lishiselwe futhi kumazinga okushisa ashiswe kuThebula 2 njengesilinganiso esincane futhi ligcinwe ezingeni lokushisa okungenani elingu-0.5 h/in.[0.2 h/cm] logqinsi noma1/2h, noma yikuphi okukhulu, nokupholiswa ngomoya.

Amakilasi 50, 51, 52, kanye 53

Ipayipi kufanele lishiselwe ngendlela efanayo kumazinga okushisa ngaphakathi kwebanga le-austenitizing futhi lingadluli izinga lokushisa eliphezulu lokucisha eliboniswe kuThebula 2.

Okulandelayo, cisha emanzini noma emafutheni.Ngemuva kokucisha, ipayipi izoshiswa kabusha ekushiseni okuphansi okuncane okuboniswe kuThebula 2 futhi ibanjwe lapho.

izinga lokushisa okungenani libe ngu-0,5 h/intshi ukujiya noma u-0,5 h, kuye ngokuthi iyiphi enkulu, futhi lipholile emoyeni.

Izingxenye Zekhemikhali

Kuyoba yisibopho somkhiqizi ukuhlola ukwakheka kwamakhemikhali epuleti kanye nama-welds ukuze ahambisane nezidingo zokucaciswa kwepuleti yezinto ezi-odiwe kanye nenqubo yokushisela yokufaka insimbi yokushisela, ngokulandelana.

Tension Test

Imvamisa yokuhlola: isifanekiso esisodwa inkatho ngayinye.

Indlela Yokuhlola: Izibonelo zokuhlola zizokwenziwa ngokuvumelana ne-QW-150 kuSigaba IX se-ASME Boiler kanye Nekhodi Yomkhumbi Wokucindezela.Ama-specimens azohlolwa ezingeni lokushisa legumbi ngokuvumelana ne-Test Methods kanye ne-Definition A370.

Ngokungeziwe KumaBanga i-Dxx, i-Hxx, i-Jxx, ne-Nxx Kumakilasi 3x, 4x, kanye nezindawo eziguqukayo ezingu-5x ze-base plate, zizonqunywa kuma-specimens asikwe epayipini elifakwe ukushisa.

Izidingo zemiphumela: Izakhiwo eziguquguqukayo eziqinile zejoyinti elishiselwe zizohlangabezana nezidingo ezincane zamandla okugcina aqinile wento yepuleti elishiwo.

Ukuhlolwa kwe-Transverse-Guided-Weld-Bend

Inombolo yezivivinyo: Imvamisa yokuhlola: kanye ngeqeqebana ngalinye, izifanekiso ezimbili

Indlela yokuhlola: Izidingo zokuhlolwa Zezindlela Zokuhlola Nezincazelo A370, isigaba A2.5.1.7 zizohlangatshezwana nazo.

Ngokuqina kodonga ngaphezulu3/ 8phakathi. [10 mm] kodwa ngaphansi kuka3/4ngaphakathi. [19 mm] Ukuhlolwa kwe-side-bend kungase kwenziwe esikhundleni sokuhlolwa kokugoba kobuso nezimpande.

Okokuqina kwezindonga3/4phakathi. [19 mm] naphezu kwazo zombili izifanekiso zizohlolwa i-side-bend.

Izidingo zemiphumela: Ukuhlolwa kokugoba kuzokwamukeleka uma kungekho mifantu noma okunye ukukhubazeka okudlulayo1/8phakathi [3 mm] kunoma iyiphi indlela akhona ensimbi yokushisela noma phakathi kwensimbi eshiselwe nesisekelo ngemva kokugoba.

Imifantu eqhamuka emaphethelweni esampula ngesikhathi sokuhlolwa, futhi engaphansi1/4phakathi. [6 mm] kukalwa kunoma iyiphi indlela ngeke kucatshangelwe.

Ukuhlolwa Kwengcindezi

Ipayipi lamakilasi X2 kanye ne-X3 azohlolwa ngokuhambisana ne-Specification A530/A530M, Izidingo Zokuhlola I-Hydrostatic.

Ukuhlolwa kwe-Radiographic

Ubude obugcwele be-weld ngayinye ye-Class X1 ne-X2 buzohlolwa nge-radiographic ngokuhambisana futhi kuhlangabezane nezimfuneko ze-ASME Boiler ne-Pressure Vessel Code, Isigaba VIII, Isigaba UW-51.

Ukuhlolwa kwe-radiographic kungenziwa ngaphambi kokwelashwa kokushisa.

Ukubekezelelana kwe-Dimensional kwe-ASTM A672

| Ezemidlalo | Ukubekezelela Inani | Qaphela |

| Ngaphandle Ububanzi | ±0.5% | Ngokusekelwe esilinganisweni esiyindilinga |

| Ngaphandle Kwe-Roundness | 1%. | Umehluko phakathi kwamadayamitha angaphandle amakhulu namancane |

| Ukuqondanisa | 1/8 in. [3 mm] | Kusetshenziswa unqenqema oluqondile olungamamitha angu-3 olubekwe ukuze iziphetho zombili zihlangane nepayipi |

| Ubukhulu | 0.01 in. [0.3 mm] | Ubukhulu obuncane bodonga bungaphansi kogqinsi olushiwo |

| Ubude | 0-+0.5in [0-+13mm] | iziphetho ezingashintshiwe |

Ukubukeka kwe-ASTM A672

Ipayipi eliqediwe ngeke lingabi nasici futhi lizoba nesiphetho esifana nomsebenzi.

Izidingo ezifanayo njengokucaciswa kwe-ASTM A20/A20M kokuqedwa kwangaphezulu kwamapuleti ensimbi.

Amaphutha kanye Nokulungisa

Ukunqunywa Kwesici

Izinga le-ASTM A672 alicacisi amazinga amukelekayo okukhubazeka kanye nenqubo yokunquma yokufaka amapayipi futhi ngokuvamile ibhekisela kumazinga afanelekile wobunjiniyela nezindlela zomkhakha.

Ukukhubazeka kwangaphakathi: Ukukhubazeka kwangaphakathi kungase kuhlanganise i-porosity, slag, inclusions, njll.

Ukukhubazeka kwangaphandle: Ukukhubazeka kwangaphandle kungase kuhlanganise ukuqhekeka, ukubola, ukuklwebheka, njll.

Ukususwa ngokugaya kabusha

Amaphutha angaphezulu angasuswa ngokugaya ngokweqile noma ngomshini ngogqinsi olusele olungekho ngaphansi kuka-0.3 mm ngaphansi kogqinsi olujwayelekile.

I-regrind depression kufanele ihlanganiswe ngokulinganayo endaweni ezungezile.

Ukulungisa Welding

Amaphutha kufanele asuswe ngokusika ngomshini noma okushisayo noma izindlela zokudayela futhi kulungiselelwe ukulungisa imigodi eshiselwe.

futhi ihlolwe ngemisebe ngokuhambisana ne-ASME Boiler and Pressure Vessel Code, Isigaba VIII, Isigaba UW-51.

Ubude obugcwele bepayipi elilungisiwe buzophathwa ngokushisa ngemva kokulungiswa ngokuhambisana nezidingo zebanga lamapayipi.

Ukumakwa kwe-ASTM A672

Ukumaka kumele kuqukathe okulandelayo:

Isihlonzi somkhiqizi, njengophawu lokuhweba noma ilogo.

Ukucaciswa kwepayipi (usayizi, ubukhulu bodonga, njll.).

Ibanga lezinto ezibonakalayo noma uhlobo lwepayipi.Isibonelo: C60-22 (isifinyezo sebanga: C60 kanye nekilasi 22).

Izinga lokukhiqiza ipayipi yi-ASTM A672.

Idethi yokukhiqiza noma inombolo yendawo yokukhiqiza.

Ukusetshenziswa kwe-ASTM A672 Steel Pipe

Embonini yamandla kagesi, i-ASTM A672 Electric Welded Steel Pipe ijwayele ukusetshenziselwa ukudlulisa isitimu kuma-boiler systems.

Embonini yamakhemikhali, ipayipi lensimbi elishiselwe i-ASTM A672 livame ukusetshenziselwa ukuthutha amakhemikhali ahlukahlukene, i-asidi, nezixazululo ze-alkali, neminye imidiya.

Embonini kawoyela negesi, ipayipi lensimbi elishiselwe i-ASTM A672 livame ukusetshenziselwa ukuthutha uwoyela ongahluziwe, igesi yemvelo, nolunye uketshezi noma amagesi.

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Tags: ASTM a672, efw, carbon steel pipe, grade.

Isikhathi sokuthumela: Apr-23-2024